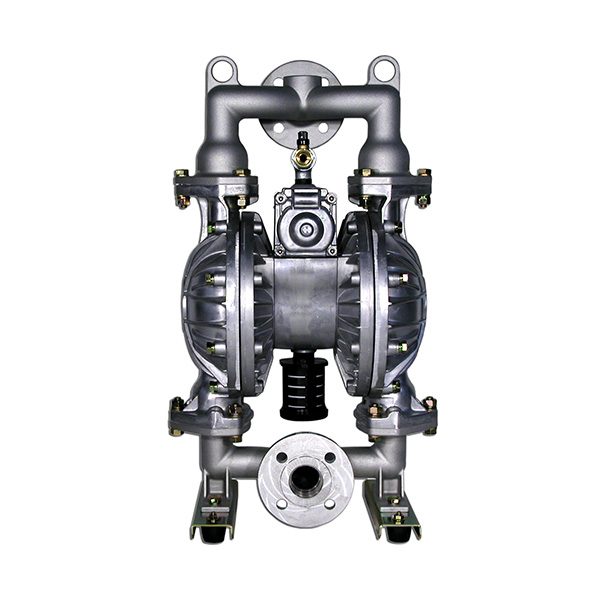

NDP-40 Pump

Request a QuoteOverview

The design of the NDP-40 air operated double diaphragm pump provides high suction lift, even at dry startup and with heavier fluids (incorporating internal check valves). No close fitting or sliding parts are at risk – the pump can run dry without damage. Pumps will run at any setting within their operating range simply by adjusting the air inlet pressure and system conditions. One pump can fit a broad spectrum of applications. Pumps transport easily to the application site. No complex controls to install or operate, simply connect an air supply, attach fluid connections, and the pump is ready to perform.

Specifications

| Port Dimensions | Intake & discharge connection: Polypropylene (PPG) 1-1/2” ANSI B16.5 #150 Kynar® (PVDF) 1-1/2” ANSI B16.5 #150 Aluminum (ADC-12) 1-1/2” ANSI B16.5 #150 (with tapped 1-1/2” Female NPT) Stainless Steel (316) 1-1/2” ANSI B16.5 #150 (with tapped 1-1/2” Female NPT) Cast Iron 1-1/2” Female NPT Air inlet (includes ball valve): 1/2” Female NPT Air exhaust (includes silencer): 1” Female NPT |

| Maximum Liquid Temperature* | Diaphragm Material Temperature Buna N 158°F (70°C) Neoprene 180°F (82°C) Santoprene® (TPO) 212°F (100°C) EPDM 212°F (100°C) PTFE 212°F (100°C) Hytrel® (TPEE) 248°F (120°C) Viton® fluoroelastomer 248°F (120°C) * The maximum liquid temperature for metal and Kynar® fitted pumps is determined by the elastomer (diaphragm material). Polypropylene pumps have a maximum liquid temperature of 180°F (82°C) regardless of diaphragm material. |

| Air Supply Pressure (All Models) | 20–100 PSI (1.4–7 kgf/cm²) |

| Discharge Volume Per Cycle | Rubber diaphragm: 0.73 gallons (2.74 liters) PTFE diaphragm: 0.37 gallons (1.40 liters) |

| Maximum Cycles Per Minute | Rubber diaphragm: 148 PTFE diaphragm: 270 |

| Maximum Size Solid | 9/32” (7 mm) |

| Maximum Dry Suction Lift | Rubber fitted pump capability: 18’ |

| Air Motor | Aluminum Air Motor-Standard Optional coating: PTFE grey coated (XP) |

| Optional | Split manifold—contact Yamada |

Features

- Outside Accessible Air Valve – inspection or maintenance can be performed without removing the pump from service

- Unified Air Valve Concept – common-size air valve assemblies reduce parts confusion & inventory

- Non-Lubricated Air Valve – reducing pumpage contamination and maintenance issues

- Pilot Valve – maintenance free modular pilot valve

- Rugged, Bolted Construction – eliminates leaks & simplifies post-maintenance reassembly.

- Diaphragm Dynamics – optimal stroke length maximizes diaphragm life & performance.

- Durable Foot & Base Support – designed to absorb weight distribution