Imagine A Ship Without Valves

In today’s modern world, a ship without valves is equivalent to a wooden ship without sails in the 1700’s. In both circumstances, the ship cannot perform the missions that it was designed to perform. In the days of “wooden ships and iron men,” if you lost your sails, you could not maneuver, and would more than likely be sunk or run aground during a battle with an enemy vessel that could still maneuver. Sails were critical to mission success. Even in that situation in a becalmed environment, the ship launched the row boats to manually pull the ship along which could prevent the vessel from grounding, but she certainly could not be successful in her main mission.

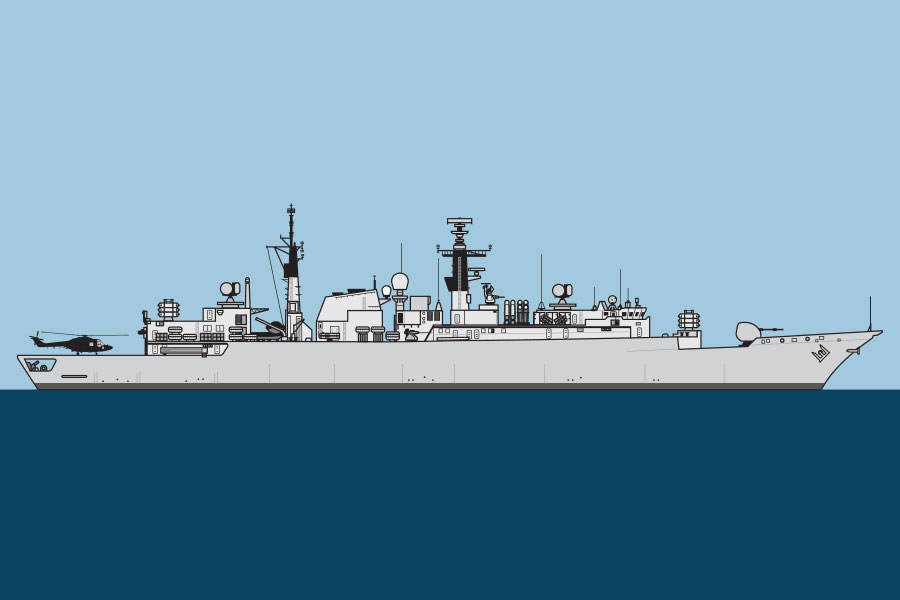

Without valves, a modern ship cannot perform any mission at all. Valves are vital flow control components of every fluid system aboard a modern vessel. Without valves:

- Helicopters and other aircraft cannot safely receive aviation fuel

- All propulsion plants require flow control of some kind

- All combat systems require electronic cooling

- All damage control and fire-fighting systems depend on them

- Most power generation devices require cooling

- All ballasting and list control systems are inoperable

Basically, a large vessel at sea without valves is a useless floating hazard to navigation. These statements are obvious to a sailor or mariner. They understand that valves are used to regulate and/or isolate the flow of fluids. The safe flow of fluids provides power, propulsion, and true mission potential. Frank Buzan, the founder of ESI Acquisition Corp doing business as JA Moody and Moody Marine Service Inc., back in 1995 intuitively understood that the United States Navy would require valves on their ships as they have for quite some time. Frank chose butterfly valves (Tyco/Keystone) to sell first as they were in common use. Those valves were rubber seated butterfly valves that were eventually replaced with high performance butterfly valves. 25 years later we are still selling Emerson’s high performance MILSPEC butterfly valves to most US shipbuilders and directly to the US Navy. One of the finest butterfly valve’s that we sell is the Vanessa (hardened seat variant) triple offset torque seated butterfly valve that we consider the finest high-performance butterfly valve in the world.

We continue to expand JA Moody’s offerings and over the years we began offering ball valves (KTM & PBM), Kunkle Pressure and Safety Relief Valves, and Hays Automatic Balancing Valves.

Because of our unique partnership with Curtiss Wright, we also offer the amazing Shutter Valve which has a valve body up to 80% smaller and lighter than a globe valve with the same flow rate. This valve has extraordinary capability and is the ONLY control valve to earn both the API 641 and ISO 15848 certifications.

JA Moody also sells a wide variety of gate, globe and check valves (Pima and Hunt). Slowly but surely, we continue to add high value products to our relatively wide range of offerings. Most recently we began offering AEVTM C-Ball Valves for cryogenic and severe service isolation applications. The breakthrough C ball valve joins the world-renowned Vanessa Series 30,000 triple offset valve to complete Emerson’s portfolio of leading isolation solutions for the LNG industry.

JA Moody is proud to offer the industry a complete line of flow control valves. To learn more about our product offerings please download our Commercial and Navy Line cards.