Covid-19 Update – September, 2020

2020 has been a very challenging year! Given the important role that we play in assisting shipbuilders and ship repair organizations in meeting their missions, we thought our clients would be interested in the latest information about how the Covid-19 environment has affected JA Moody and Moody Marine Service Inc as well as our top three manufacturers of Navy products.

JA Moody

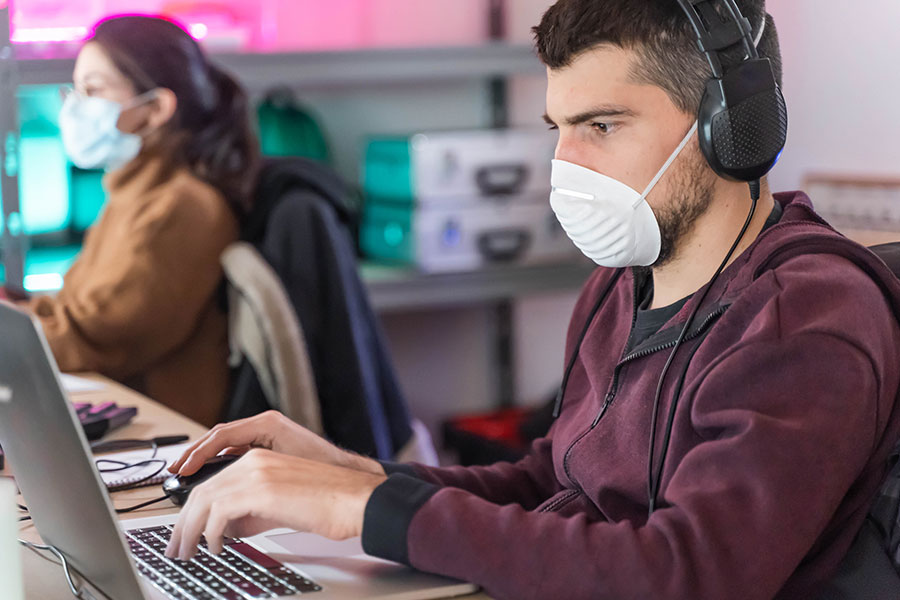

As we have done from the very beginning of the Covid-19 threat, JA Moody has encouraged as many employees as possible to perform their jobs remotely. All outside sales team members, selected inside sales team members, all accounting and IT staff, government contracting and expediting staff, and selected executive managers and ownership, are effectively performing remotely. Some functions naturally require a physical presence such as warehousing, packaging, shipping and receiving, as well as assembling Rotork manual gear operators to valves prior to shipping. Since Covid-19 began, JA Moody has had a team of about 5 people coming to Malvern each day to make sure that our shipments get done as safely and quickly as possible. We achieved our Covid-19 zero infection rate through a combination of using our Personal Protective Equipment (PPE) and detailed interviews with the small team who comes to work every day. We also initially denied access to our facilities to everyone else. Just recently we allowed government inspectors into our Malvern, PA facility for source inspection after first verifying that all mandated precautions published by the CDC had been met. We will continue to do so on a case by case basis.

Moody Marine Service, Inc

As you may know, Moody Marine Service Inc (MMS), runs an extremely tight ship and is fully open for business. MMS is continuing to provide service to their customers which includes repair and/or service of a wide variety of marine (primarily Navy) valves, valve actuation and control system. The MMS team must remain in their repair facilities or hit the road to support customers who require onsite support. MMS performs repair and services in the Jacksonville, FL, Chesapeake, VA and San Diego, CA areas, and the team not only performs ship to shop support but also travels to shipyards and ship builders’ facilities to support the repair and/or building of new vessels as appropriate. The MMS team is particularly at risk when they go into shipyards and shipbuilder facilities when they must work side by side with shipyard personnel. Given all of that, MMS’s 0% Covid-19 infection rate is an outstanding testimonial to their attention to safety and health. The MMS team continues to enjoy a customer satisfaction rate of nearly 100% and is considered the “go to” service organization for many challenging assemblies, testing and/or grooms, services, and repairs

Update from Curtiss Wright, NuTorque

As the impacts of the Covid-19 crisis became apparent, Curtiss-Wright Nu-Torque developed an action plan to continue to support our customers while protecting our employees. As a critical infrastructure supplier to the defense industry, Curtiss-Wright was exempt from certain executive orders issued by New York state. Regardless, due to practical matters of employees that were actually or potentially infected with the virus and to minimize risk across the organization, a number of actions were taken, including:

- Engagement of the Senior Leadership Team to define and document revised protocols to be utilized

- Use of CDC, New York State and other requirements for guidance in development of best practices

- Offsite quarantine of infected, potentially infected or high risk employees

- Work from home assignment where possible for knowledge workers

- Split shifts for employees who could not meet WFH requirements

- Daily temperature monitoring, regular deep cleaning and implementation of shielding, signage and wok area reconfiguration

- Limits to employee travel and on site visitors

- Social distancing, PPE utilization and extensive use of remote meetings

In the initial stages of the pandemic, Curtiss-Wright and many of our suppliers were affected with lost work days. While recent trends have been positive, and we have been able to return some employees to a normal work schedule, we will continue to utilize these modified protocols until acceptable levels of risk can be attained.

Update from Emerson

Korea was pretty much unaffected from Covid.

Vanessa in Italy was running at 60% capacity at peak Covid there. They worked with the Italian government to get approvals to stay open as a critical business. As part of that approval they had to publish procedures and have state inspectors visit the facility to ensure adequate procedures were in place and being followed.

Navy KLOKs are made in Pasadena which was unaffected, they were approved as an essential business and practice CDC guidelines in the facility; however, the component supply chain from India was greatly disrupted due to the situation in India. Our factory in Pune was open during the pandemic as an essential business but capacity was around 25% due to strict quarantine procedures (only employees located in the same zone as the factory were able to come into the facility). Transportation was also severely impacted so while the plant was operational it was challenging getting the product to port.

Update from Pima Valve

- HVC/MB has had a negligible impact to operations due to COVID-19. Due to both locations being part of the critical infrastructure for the United States/Canada, respectively, operations were able to continue uninterrupted.

- Both locations continue to follow the guidance of federal, state (provincial) authorities (such as the Centers for Disease Control) including practicing social distancing, wearing face coverings, taking temperatures, quarantining as required, etc. Further, remote working is allowed (function dependent).

JA Moody will continue to provide updates to our clients as necessary. Should you have an immediate concern or question please contact us or call 610-647-3810.